How Laser Engraving Works: A Behind-the-Scenes Look

Laser engraving has transformed the way we personalize and brand items—especially leather products. Whether you’re curious about what happens when a laser meets a leather wallet or considering starting your own customization business, understanding how laser engraving works is key. Let’s take a behind-the-scenes look at this fascinating process, using leather goods as our prime example.

What Is Laser Engraving? The Basics Explained

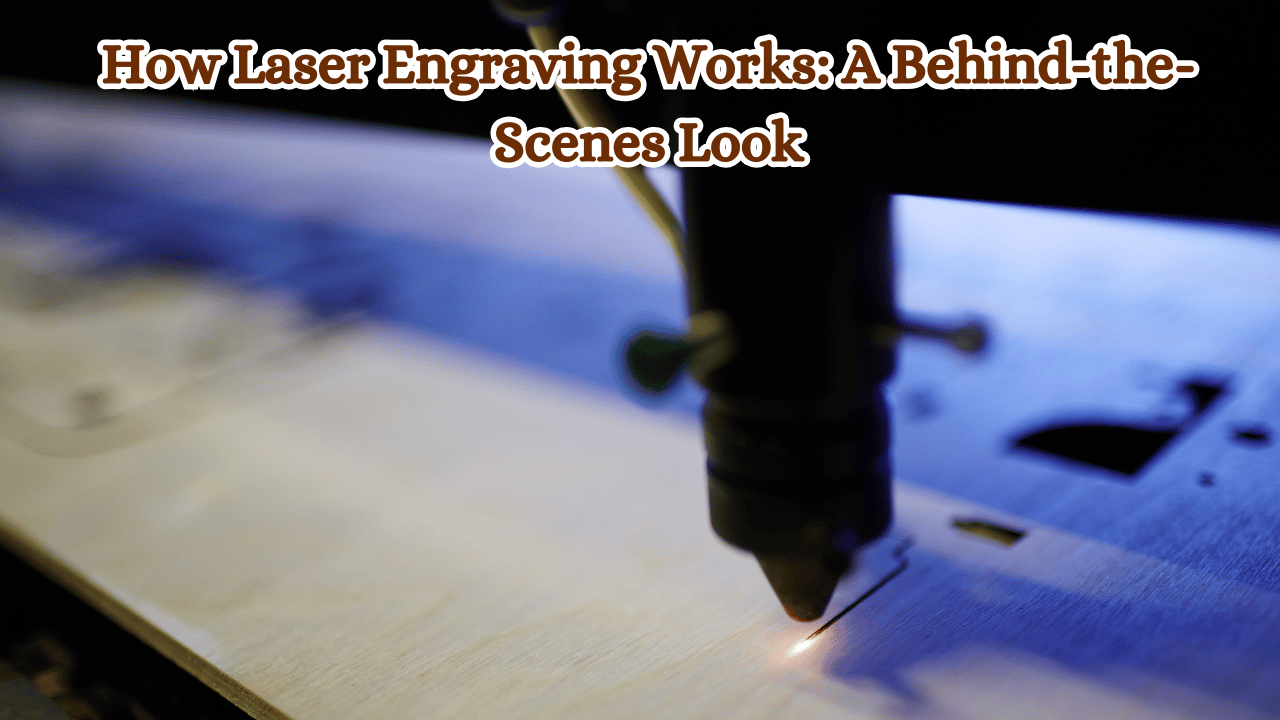

In the simplest terms, laser engraving is the process of using a highly focused beam of light (the laser) to etch or mark the surface of a material. For leather products, this means creating detailed designs, logos, or personalized messages with precision and speed.

In the simplest terms, laser engraving is the process of using a highly focused beam of light (the laser) to etch or mark the surface of a material. For leather products, this means creating detailed designs, logos, or personalized messages with precision and speed.

How Does Laser Engraving Differ from Other Methods?

- Traditional Stamping: Uses metal dies to press a design onto the material, which can wear out over time and lacks fine detail.

- Hand Engraving: Offers a personal touch but is slow and requires significant skill.

- Laser Engraving: Delivers crisp, repeatable results quickly and can handle very fine lines—ideal for detailed work on wallets, belts, or custom keychains.

Think of laser engraving as drawing with light: the laser “burns” away the top layer of the leather, leaving a permanent mark. The best part? The process is non-contact, meaning the tool never actually touches the product.

The Laser Engraving Process Step-by-Step (with Leather Examples)

Laser engraving might sound futuristic, but the process is surprisingly straightforward in practice:

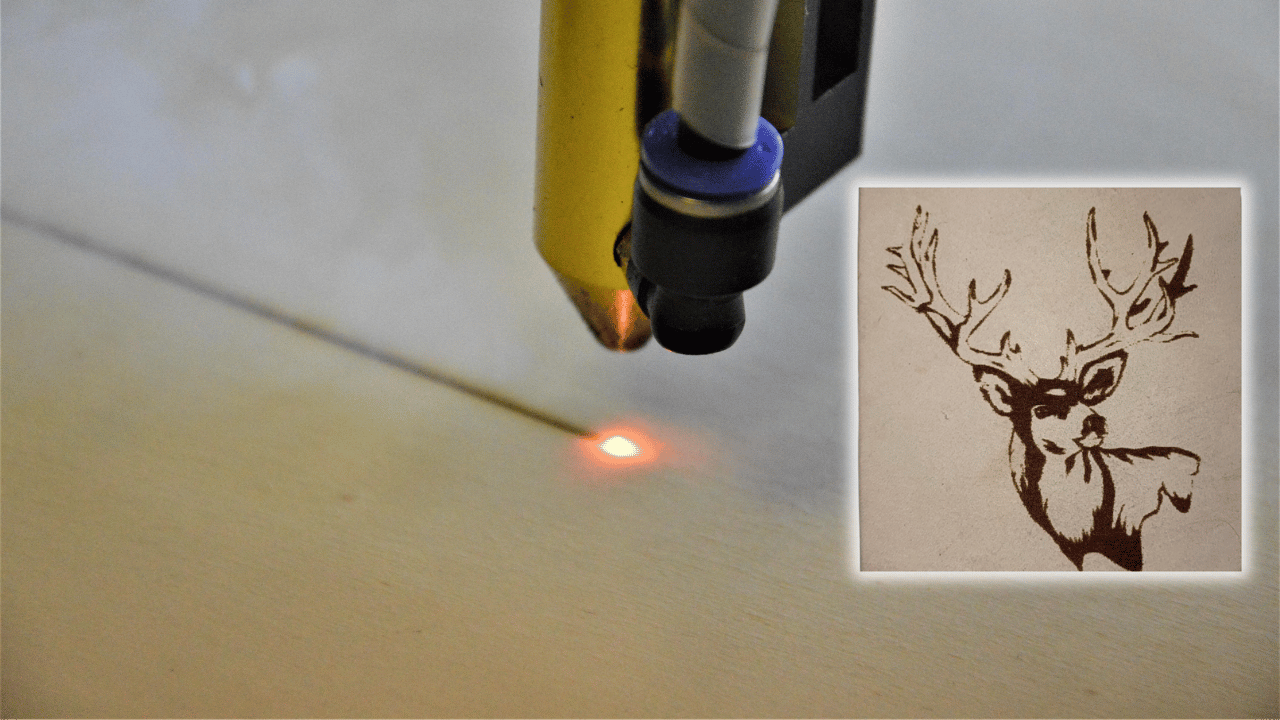

- Design Creation: First, a digital design is created using software like Adobe Illustrator or CorelDRAW. For example, you might want to engrave your initials or a company logo on a leather journal.

- Material Placement: The leather item (say, a wallet) is placed into the laser engraving machine, secured flat to ensure accuracy.

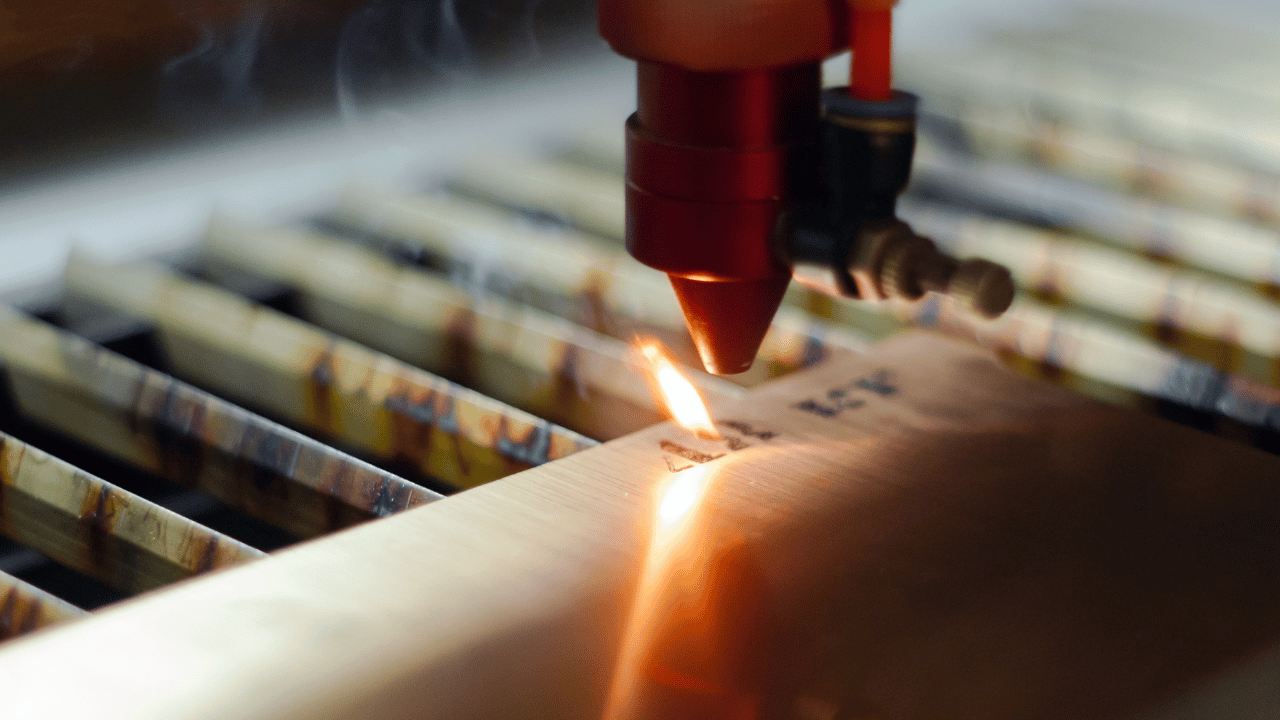

- Machine Settings: Settings such as laser power, speed, and frequency are adjusted based on leather type and thickness. In my experience, a common mistake is using too high a power, which can over-burn the leather and cause unwanted charring.

- Engraving: The laser follows the digital design, etching it onto the leather’s surface.

- Finishing Touches: After engraving, residue is wiped away. On leather, this might mean brushing off soot or applying a finishing balm to enhance the contrast.

For example:

A client wanted custom keychains for their business. We designed a clean logo, chose a natural vegetable-tanned leather, and carefully calibrated the laser’s power. The result? Dozens of crisp, professional-looking keychains—each one identical.

Actionable Tips for Better Laser Engraving on Leather

Ready to get the most out of laser engraving? Here’s what works in practice:

Ready to get the most out of laser engraving? Here’s what works in practice:

- Choose the Right Leather: Natural, undyed leathers engrave best and produce a strong contrast. Dyed or heavily treated leather may yield less predictable results.

- Test First: Always run a small test on a scrap piece of leather. This avoids costly mistakes on finished products.

- Mind the Details: Small fonts and intricate logos look great with lasers but may require slower speeds to maintain clean lines.

- Use the Right Tools: Software like LightBurn can make the design and transfer process much smoother for beginners and pros alike.

Laser engraving isn’t just about aesthetics—it’s about efficiency, consistency, and unlocking creative possibilities, especially for those passionate about quality leather goods.

Frequently Asked Questions

- Will laser engraving damage my leather products?

No, when done correctly, laser engraving only removes the surface layer, leaving a permanent, detailed mark without compromising the leather’s integrity. - Can I engrave colored or finished leather?

Yes, but results can vary. Natural leathers usually produce the best contrast. Finished or dyed leathers might react differently, so always test a sample first.

If you’re looking to personalize leather products or explore new creative avenues, understanding laser engraving is your first step toward professional results. With the right approach and tools, you can achieve impressive, lasting designs every time.