Popular Materials for Laser Engraving: Leather, Wood, Metal & More

Laser engraving offers a world of creative possibilities, allowing artisans, businesses, and hobbyists to personalize and customize a wide array of materials. Understanding the unique properties of each material can enhance your projects, ensuring quality results every time. Here, we explore some of the most popular materials for laser engraving: leather, wood, metal, and more.

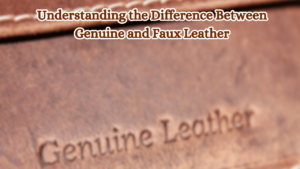

Leather: Luxury and Versatility

Leather is a favored choice for laser engraving due to its luxurious feel and versatility. Whether crafting personalized wallets, belts, journals, or gun holsters laser engraving can impart intricate patterns and logos with precision. Leather reacts well to laser cutting, resulting in clean edges and deep, contrasting engravings that don’t fade over time.

Leather is a favored choice for laser engraving due to its luxurious feel and versatility. Whether crafting personalized wallets, belts, journals, or gun holsters laser engraving can impart intricate patterns and logos with precision. Leather reacts well to laser cutting, resulting in clean edges and deep, contrasting engravings that don’t fade over time.

When working with leather, it’s crucial to consider the type and treatment of the leather. Vegetable-tanned leather works exceptionally well, offering a rich, dark burn. It’s essential to adjust the laser’s power and speed settings to prevent burning the material excessively. The result is a sophisticated finish that enhances the natural beauty and texture of leather.

Wood: Natural Beauty Meets Personalization

Wood is another popular medium for laser engraving, offering endless possibilities from decorative items to functional pieces. This material is appreciated for its natural beauty, with each type of wood yielding different results. Hardwoods like oak and walnut provide fine detail and contrast, while softer woods such as pine offer a lighter, more rustic appearance.

The key to successful wood engraving lies in understanding the grain and hardness of the wood, which can affect the engraving depth and clarity. Different woods may require adjustments to laser settings to achieve the desired outcome. Additionally, wood can be easily cut with lasers, allowing for intricate shapes and designs, making it ideal for custom signage, home decor, and more.

Metal: Durability with a Modern Edge

When it comes to durability and a modern aesthetic, metal is an outstanding choice for laser engraving. Commonly used metals include stainless steel, aluminum, and brass. Metals require a higher laser power compared to other materials. However, with the right settings, laser engraving can produce precise, permanent marks without compromising the integrity of the metal.

When it comes to durability and a modern aesthetic, metal is an outstanding choice for laser engraving. Commonly used metals include stainless steel, aluminum, and brass. Metals require a higher laser power compared to other materials. However, with the right settings, laser engraving can produce precise, permanent marks without compromising the integrity of the metal.

Engraving on metal is perfect for industrial applications, creating custom machine parts, or personalizing items like jewelry and awards. The process can also produce a striking contrast, especially on anodized or coated metals, making your engravings stand out with clarity and sophistication.

Conclusion

Laser engraving provides a unique opportunity to transform everyday materials into personalized works of art. Whether working with leather, wood, metal, or exploring other materials like acrylic and glass, understanding the properties and requirements of each can significantly enhance your projects. By harnessing the power of laser technology, you can achieve professional, durable, and stunning engravings every time.